Features

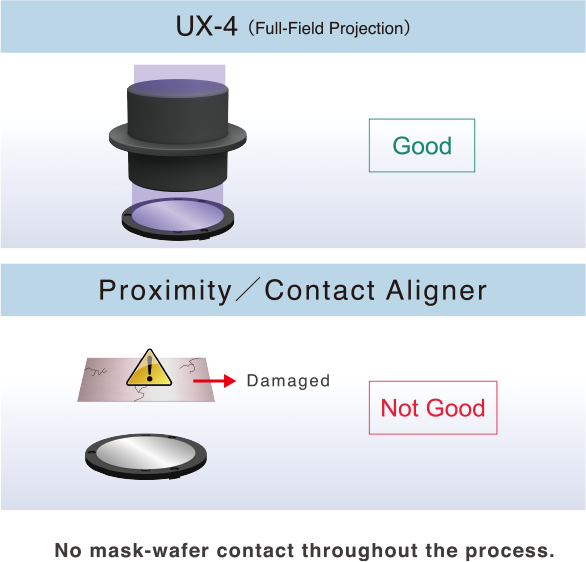

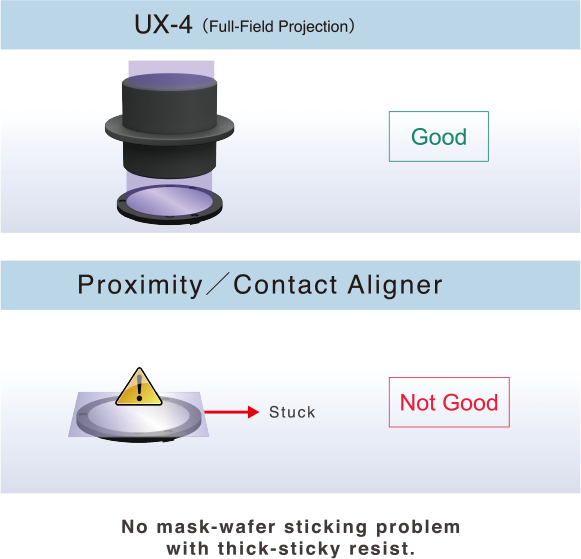

Mask damage free

The projection lithography tool causes no damage to the mask because it has no contact between the mask and the wafer. We developed the optical system that allows exposure of a large field with low lens distortion, suitable or high-volume production with high yield and low maintenance cost, something not with possible proximity/contact mask aligners.

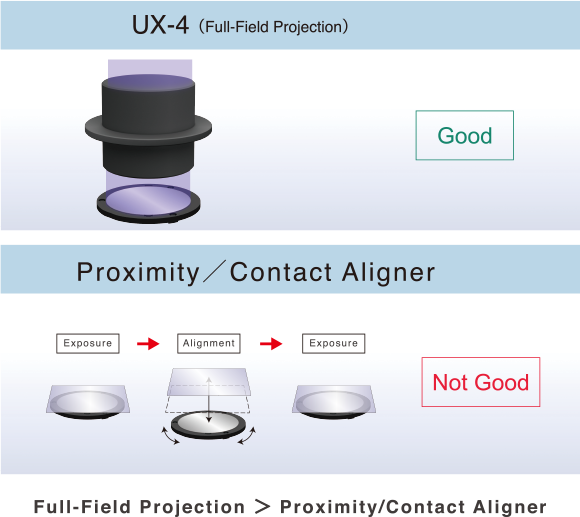

High Productivity

In addition to the mask maintenance cost, the exposure field size of this projection mask aligner is for a whole wafer and throughput will be better than steppers. Total CoO(Cost of Ownership) will be the best compared to proximity/contact mask aligners and steppers.

Mask compatibility

Customer's existing masks for conventional aligners can be used for UX-4. No special mask is needed.

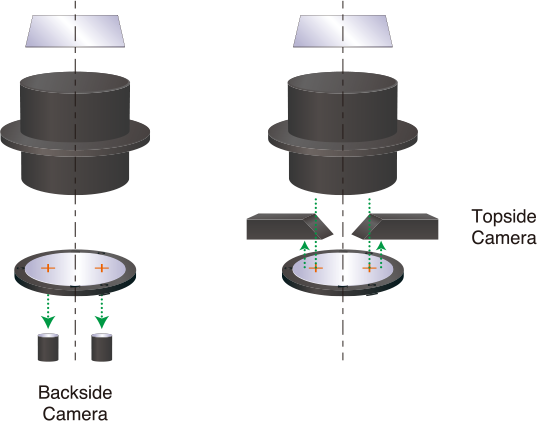

High precision alignment

UX-4 has flexible illumination methods (bright-field or dark-field illumination) and several auto aligment algorithms with special softwares for Top-side alignment, Back-side alignment(Bottom-side alignment), and "Infrared alignment (for embedded marks in wafers). Selecting the best aligment way for each alignment marks enhances alignment precision.

Even without dedicated alignment marks, you can still register part of your unique trace pattern to the alignment system and use the Pattern Matching method.

It enables selection of various auto-alignment algorithms (reference method, center-of-gravity detection, and multipoint alignment) corresponding to alignment marks.

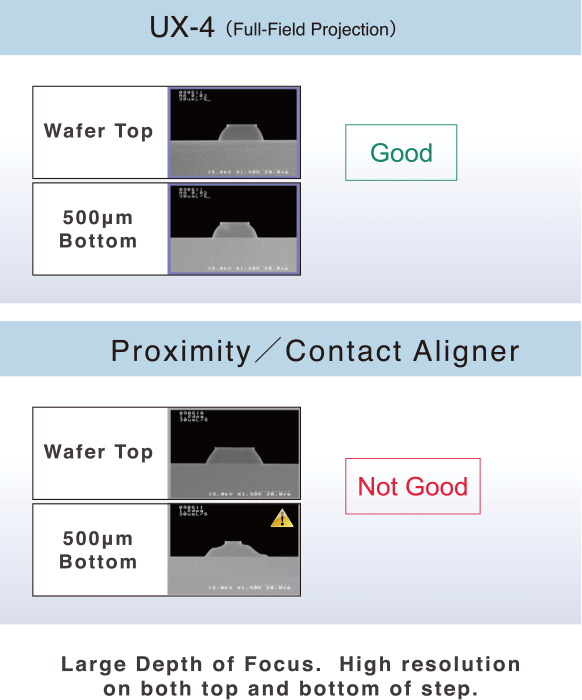

3D-Dimensional Exposure

Large Depth of Focus enables high resolution on both top and bottom of step in 3D lithography.

Thick Film Resist Support

No mask-wafer contact generates no mask-wafer sticking problem with thick sticky resist.

Large DOF(Depth of Focus) enables good shape patterning with thick resist.

Also, full field exposure for a whole wafer is effective with thick resist which requires a high dose amount.

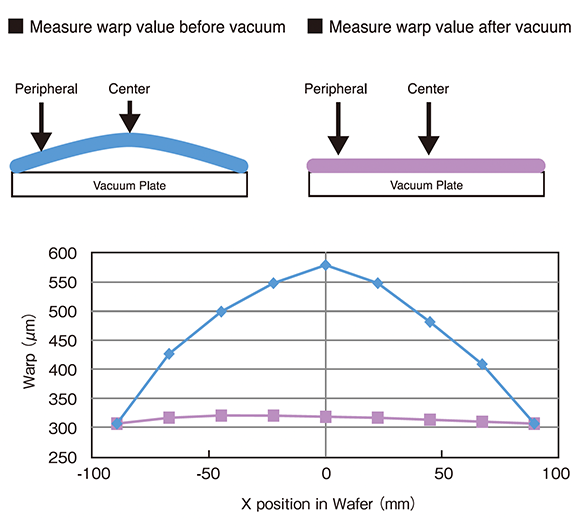

Wafer handling know-how

USHIO has expertise for wafer handling proven by various experiences. According to customer specifications such as warped wafers, thick wafers, thin wafers. etc, we applied such know-hows to the special designs for end effector and wafer suction plate.

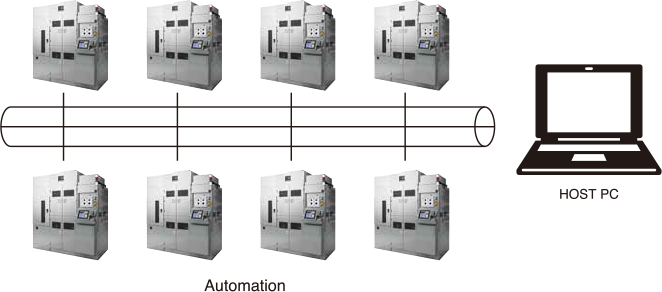

Automation

USHIO has a lot of options for automation such as SECS/GEM, Inline link system.

Customers can control USHIO's projction mask aligner from a host computer in customers' factrory without human operation.

Not only for outside of the tool, its inside can be automated.

Mask auto changer with mask library can be installed, preventing human errors.